- Nielsen Enterprises

- Software

- Surfcam Waveform

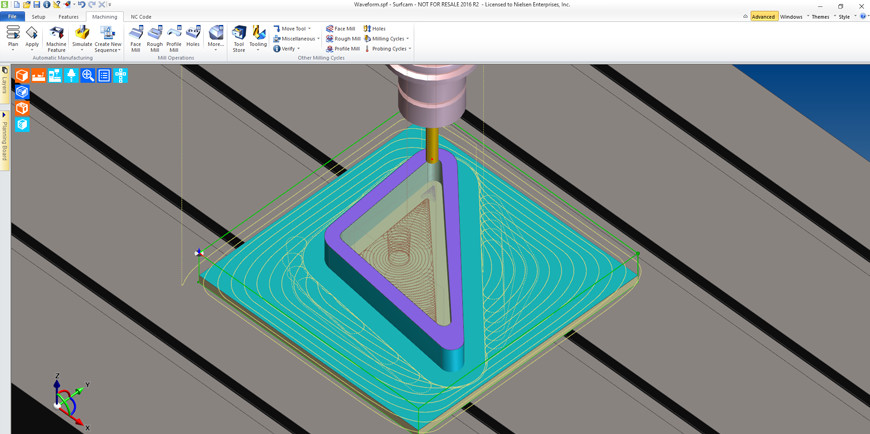

Surfcam Waveform

Waveform machining for milling and turning is standard with Surfcam

no additional purchase necessary

Waveform maintains a constant chip load for high speed machining.

The tool moves in a smooth path to avoid sharp changes in direction, maintaining a constant/high feedrate.

Feature Highlights

- Reduces cycle time

- Improves tool life

- Lengthens machine maintenance cycles

- Keeps constant chip load

- Cuts deeper and faster

Constant Engagement With Material

Although concentric milling looks much simpler at the first glance the problem is that the tool “digs” into each corner causing the tool to overload, leading to reduced tool life or tool breakage. In reality the machine tool operator may have to reduce the cycle feed rate to compensate and thus, increase the manufacturing time.

As Waveform maintains a constant engagement the feed rate can remain at the optimal value throughout the cycle. This will improve the tool life and greatly reduce the risk of tool breakage.

The Waveform Pattern

To maintain a constant chip load the cycle uses the philosophy that we machine from “Stock to part”. This reduces the amount of intermittent cuts, particularly on external regions, which means the tool is engaged with the material for longer without lifting clear. Traditionally, cycles generally offset the component until they meet the stock. This can lead to the generation of sharp corners and discontinuous tool paths.

For pocket regions the tool will helical in to depth at the center and open the pocket up so that it can create a continuous spiral cut until the edge of the pocket is reached. Any remaining corners are then removed.

Automatic Adjustment for Tool Engagement

To maintain the tool engagement and the chip load the tool path is automatically adjusted to compensate.

When cutting into a concave area tool engagement is increased. The cycle adjusts the step over between the passes to compensate and maintain the desired engagement.

When cutting a convex area the opposite affect occurs. As the material falls away the tool path step over is increased to maintain the desired engagement.

Smooth Tool Path

By ensuring the cycle produces a smooth tangent tool path, the velocity of the machine can be maintained and the desired feed rates achieved. This also has the benefit of reducing shaking and vibration on the machine and component.

Linking the Tool Path

The links within the cycle are aware of the rapid and High Feed rate settings for the machine tool. When moving to the next cut the cycle will automatically choose the fastest method to get to that point. In localised areas the tool will stay at depth, but on long moves the tool retracts and rapids to position.

Stay at Depth

When the tool stays at depth the path will automatically move around the stock when required. The moves at depth can be at high Feed and allows the user to specify a small retract to stop the tool rubbing on the floor of the part.

Simple Interface

We have ensured that the cycle uses the information in the part and Code Generator where possible and kept the interface to only 3 modifiers that the user can adjust for the waveform pattern. This ensures the cycle is easy to apply and is integrated into the main Roughing cycle.

Full Cut Depth Machining (High Speed Machining)

Waveform Roughing greatly improves standard roughing by ensuring a constant volume of material is removed. In addition, this also opens up the way to use high speed machining, particularly for hard materials.

Cutting along as much of the flute length as possible distributes wear evenly along the entire flute length, rather than just the tip. The radial cut depth is reduced to ensure consistent cutting force allowing cut material to escape from the flutes. Tool life is furtherer extended as most of the heat is removed in the chip.

An example of the feed rate and depth of cut that can be achieved in hard materials, both in Metric and Imperial measurements, is listed below.