- Nielsen Enterprises

- Services

- Foundry Tooling

While metal casting has been around since 3200 B.C. and the process is largely the same, the technology used to produce foundry tooling has changed drastically. Nielsen Enterprises was one of the first companies to incorporate CNC machining and CADCAM software in the foundry tooling process. Today we remain one of the leading foundry tooling / pattern shops in the midwest by using the latest technology and processes to produce the highest quality tooling possible. Whether you are looking to have a new part cast or you would like to replace a complex weldment castings are great avenue to explore.

Red Board - Polyurethane - Master - Patterns

Sand castings make up roughly 70% of cast parts and red board patterns are usually the cheapest / quickest option while still maintaining a good surface finish

Cost - red board is easier to machine saving you money.

Durability - compared to older wood patterns, red patterns last longer and have better finish quality.

Short lead times - maching redboard is faster, helping to get your tooling produced quickly.

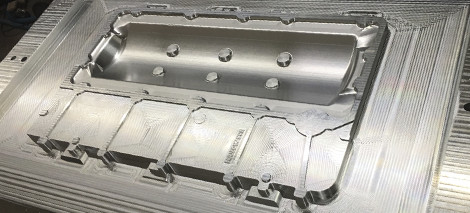

Machined Aluminum Patterns and Matchplates

Aluminum patterns provide a more stable option and allow for thinner parts. When parts have complex geometry, offset partings or they are thin, machined matchplates are the best option for thin parts.

Durability - compared to wood or red board patterns, aluminum patterns last longer and are more stable. They can also be welded making repairs and changes easier.

Cost - aluminum tooling is more affordable for medium to high volume runs compared to a permanent mold.

Fully Machined Aluminum Matchplate - Choosing a fully machined aluminum matchplate allows you more flexability. Gating can be machined in making tooling easier to manage, machined matchplates have lower scrap rates saving you money.

Permanent molds

If you plan on very high volumes or need extremely nice surface finish, permanent molds are the preferred option. Common metals cast in Permanent molds include: aluminium, magnesium, copper, tin, zinc, and lead alloys.

Cores

We are experts at core assemblies and try to save you money by eliminating them whenever possible. When cores are needed we can assist you in the design of core assemblies small or large. Once designs are produced we can machine coreboxes usually called cold boxes when made from red board or shell boxes when made from iron.

Communication

Questions | Quotes | Support

We want to hear from you

Customer Service

We value your business and are passionate about manufacturing

Fast Delivery

Deadlines are tight so we deliver your parts quickly