- Nielsen Enterprises

- Software

- Surfcam Intelligent Manufacturing

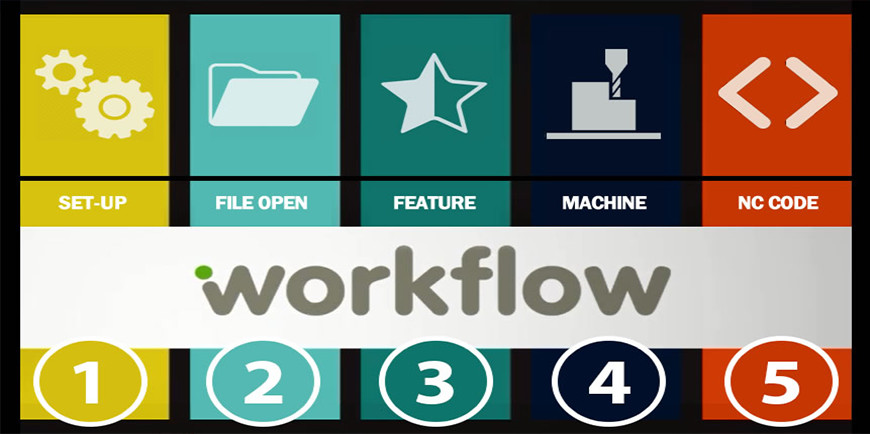

Workflow

Designed for manufacturers to reduce costs, improve quality and hit shorter lead times. Operators will be able to apply toolpaths to prismatic parts in minutes.

Feature Highlights

- Interactive, Intuitive and Informative

- Built-in machining strategies automatically create cutter paths

- User defined toolpath creation

- Ribbon bar interface

- User navigation and user guidance

Accelerated generation of CNC code

Surfcam Workflow understands the component topology and the required manufacturing environment therefore accelerating toolpath generation.

Workflow will have a significant impact on shortening programming time, and because it is so simple to operate, the learning curve for new users is considerably reduced.

Workflow - A Five Stage Process

- File

Adopting the common Microsoft Office 2010 theme, this allows users to efficiently manage files and folders.

- Set-Up

Dynamically sets up datum position, adds stock and fixtures through the interactive stock, fixture and machine manager functions.

- Features

Using Surfcam’s powerful automatic feature recognition, all types of manufacturing features can be found.

- Machining

The Planning board applies a suggested order of manufacture, which can be manipulated easily by drag and drop techniques.

- NC Code

The toolpath is then simulated in the machine simulator, checking for collisions, gauges and limit over travel. The toolkit can be reviewed and edited before NC code is generated to complete the five-stage Workflow process.